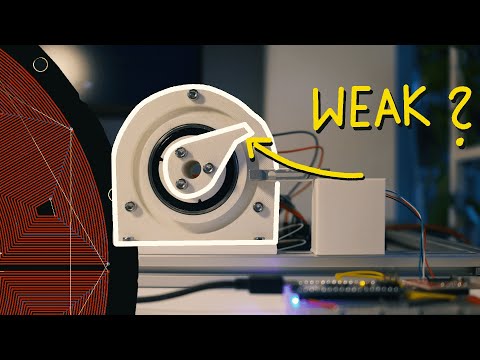

3D printed materials have come a long way in the last decade or so as printers have become more and more mainstream. Printers can use all kinds of different plastics with varying physical characteristics, and there are even printers now for other materials like concrete and metal. But even staying within the realm of the plastic printer can do a lot of jobs you might not expect. [Camden Bowen] recently 3D printed a single-piston engine which nearly worked, and is back with some improvements to it thanks to a small carburetor.

The carburetor itself isn’t 3D printed (although not from lack of trying) — it’s on loan from a weed eater, and is helping to solve a problem with the fuel-air mixture of his original design. Switching from butane to a liquid fuel also solved some problems as well, and using starter fluid also helped to kick off the ignition. Although it ran for a short period of time over several starts, the valve train suffered some damage with the exhaust valves melting in place to the head. This is actually a problem common to any internal combustion engine like this, especially if the fuel-air mixture is too lean, there’s incomplete combustion, the valves aren’t adjusted properly, or any number of other problems. In this case it seems to have been caused by improper engine timing.

It’s actually noteworthy though that the intake valves weren’t burned, meaning that if the engine can be tuned to allow for complete combustion before the exhaust gasses leave the combustion chamber, the plastic 3D printed head and valve train will likely survive much longer operational periods. We’ll certainly look forward to the next iteration of this engine build to see if that’s the case. If 3D printed piston engines aren’t your speed, though, take a look at this jet engine which uses a 3D printed compressor.

Thanks to [Rickert] for the tip!

0 Commentaires